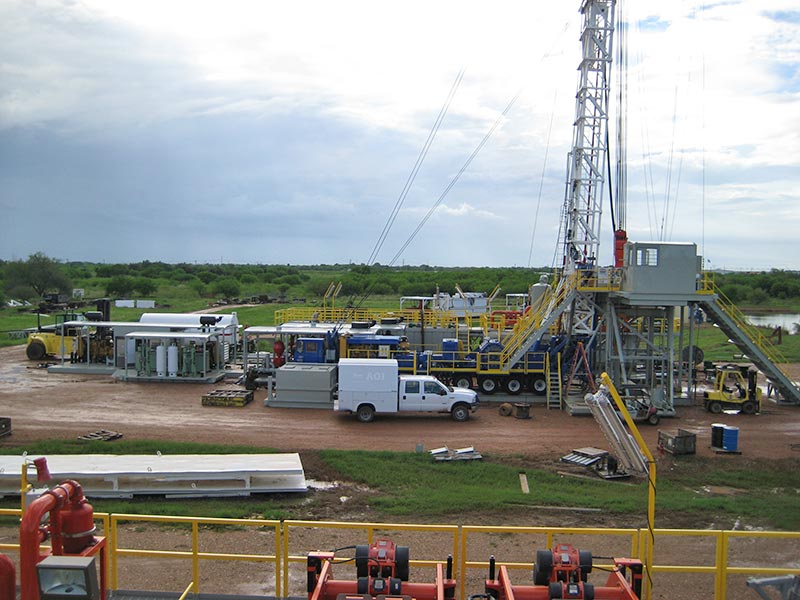

We provide a variety of structural engineering services for the oil and gas industry, commercial and institutional owners

What we do

Training & Consultancy Services

- Human Capital Development

At SOKONO, we design, develop and deliver cutting edge education and training programs for professionals in the petroleum and allied industries.

SOKONO has a comprehensive training modules and depth of experienced faculty on capacity development for technical and non-technical staff at all levels of operations in the oil and gas industry with emphasis on modern skills/techniques and global best practices.

At SOKONO, we pinpoint urgent skills gaps and design practical learning modules covering a complete learning lifecycle for individuals, asset-teams that ensures positive outcome in the oil and gas industry. Our courses presentation include theoretical aspects, discussion of case studies and field scenarios. We focus on ensuring excellence of execution and optimum client outcome and how our participants learn and not only what they learn. The date, location and course content for all modules are flexible depending on your company’s operational urgent operations/skills needs.

Oilfield Services

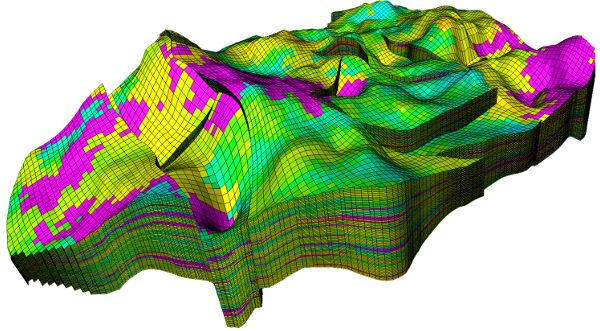

- Integrated Reservoir Studies

A well-developed reservoir description is beneficial for managing the asset’s daily operations as well as long-term planning. Integration entails utilizing all available information about the reservoir in order to gain a better understanding of it. Our expert team conducts integrated reservoir studies to assist clients in better understanding and describing the dynamic behavior of their hydrocarbon reservoirs in order to predict its future performance under various development and production strategies for both greenfield and brownfield projects.

- Field Development Plan (FDP)

Our technical strength, competence and experience in the oil and gas industry leverage our business strategy to assist our clients in the oil & gas field development planning (FDP) for operational and strategic decision-making throughout the field’s life cycle, including acquisition, exploration, appraisal, and development. We deploy state-of-the-art software to generate fully probabilistic assessment of conceptual field development by integrating subsurface geological uncertainties with operational and economic uncertainties.

- Production Optimization Service

Our production optimization services include asset screening, analysis, and recommendation – all with the goal of identifying quick wins (subsurface and process engineering) in short-, medium-, and long-term strategies. It entails quantifying, analyzing, modeling, prioritizing, and implementing actions to increase a field’s productivity (reservoir/well/surface facilities).

Additionally, our techniques for optimizing production include well types, well completions, artificial lift, stimulation methods, matrix stimulation, and hydraulic fracturing.

- Well Test Analysis and Interpretation

Our highly technical team assists our client with well test design, planning, operational readiness, data quality assurance, pressure transient analysis/bottom hole pressure (BHP) survey and interpretation, as well as report writing.

SOKONO’s well test analysis and interpretation service is one of the practical and indirect methods for characterizing our clients’ wells and reservoirs’ properties in order to estimate near-wellbore permeability, skin, flow capacity, fluid mobility, transmissibility, completion efficiency, reservoir storativity, and average reservoir pressure, as well as to determine the degree of communication between points in a reservoir.

- PVT Sampling, Analysis and Data Interpretation

We performed both surface and subsurface reservoir sampling and perform the following major black oil and gas condensate PVT experiments:

- Constant Composition Expansion (Oil)

- Differential Vaporization (Oil)

- Separator Test/Flash Liberation (Oil)

- Constant Composition Expansion (Condensate Gas)

- Constant Volume Depletion (Condensate Gas)

- Viscosity Measurement

- Compositional Analysis

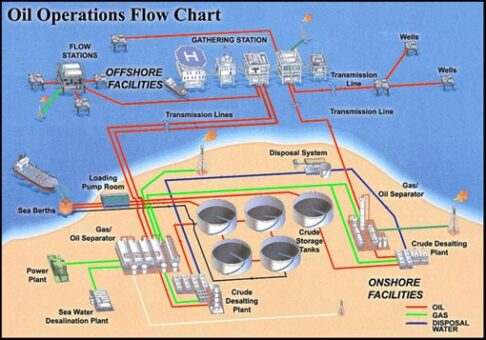

- Integrity Studies on Oil and Gas Installations

Our Asset Integrity Management team is responsible for coordinating the efficient and cost-effective implementation of inspections and integrity management programs for our clients. This includes all onshore and offshore structures, pipelines, stationary and rotating equipment, and piping systems, etc.

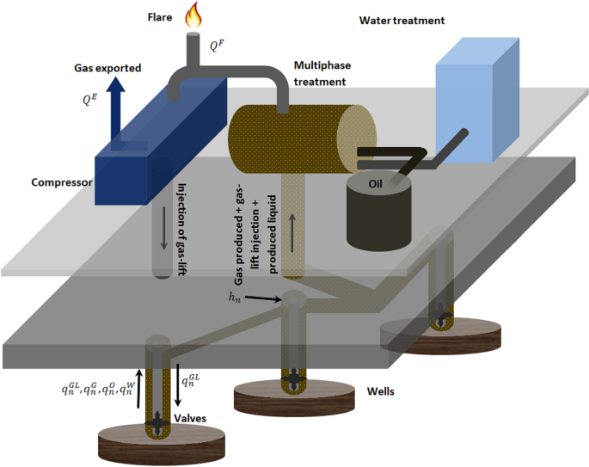

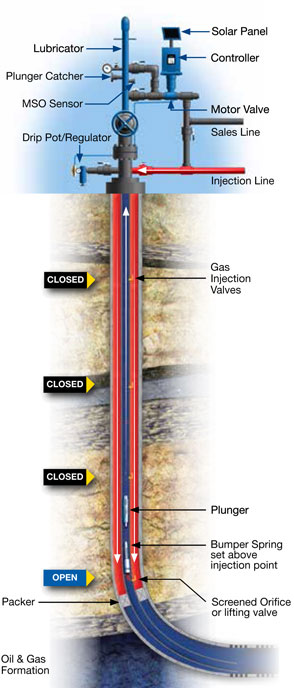

- Gaslift and ESP Optimization Study

The gas lift optimization facility determines the most efficient way to allocate lift gas, ensuring that production targets are met. If production targets are not met, it determines how to make the best use of available lift gas by allocating it preferentially to the wells that can make the best use of it.

Our seasoned production optimization team offers innovative solutions to assist our clients:

- To determine the optimal lift gas injection rate and depth, as well as to design the gaslift well’s operating and unloading valves.

- For wells that require pumping, select the best pump, motor, and cable for the ESP to be installed in order to maximize production efficiency.

- Gas lift optimization for individual wells (How much lift gas does each well require to meet its individual production target?).

- Gas lift optimization within a group of wells (How much lift gas does the group of wells require to meet its production target?).

- Addressing insufficient lift gas (How should it be distributed between individual wells?).

- Optimizing gas lift in a simple network (How does the allocation of lift gas need to be moderated to account for pressure losses in the flowline?).

- Wellhead/Valves Maintenance Services

Consistently high-quality and efficient production can breed complacency about the wellhead’s integrity and a disregard for routine maintenance. Inadequate maintenance of critical components can have a detrimental effect on mechanical assemblies and equipment failure, which can be avoided by servicing valves, performing pressure and function tests, and monitoring the general wellhead condition and operational trends. We provide first-line, second-line, and ad-hoc services, including the following:

- Xmas tree valves repairs or gate and seat assembly

- Choke or bean box replacement

- SSV pilots repair/change or resetting

- Xmas tree change out after the well has been killed and secured

- Maintenance of wellhead control panels

- Process Automation And Optimization

Our business process automation unites business activities into streamlined workflows to digitally transform your company. We increase organizational efficiency by improving processes. Our system optimization helps organizations to reduce redundancies and forecasting changes.

- Process control and system implementation : At SOKONO, our process control and system implementation covers design, installation, configuration and FAT/IFAT in full compliance with recognized industry standards, safety standard and various client specification

- Development of systems documentation: It covers functional design specification, I/O list and related drawings

- Control panel design, fabrication and installation based on design specifications: At SOKONO, our team is responsible for site service s such as surveys pre-commissioning, start-up, routine maintenance, SAT and customer technical support services.

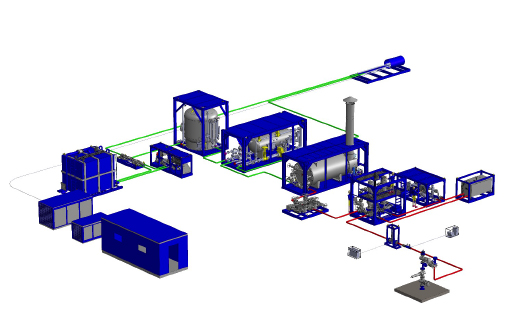

Engineering, Design, Construction and Installation and Commissioning (EPCIC)

- Feasibility Studies

- Conceptual Studies

- Front End Engineering & Design (Feed)

- Detail Engineering Design

- Topside Facilities Modification/Upgrade

- Pipeline and Infrastructure Construction & Maintenance

SOKONO Engineering, in collaboration with its local and foreign technical partners, designs oil and gas facilities ranging from separators, heaters, compression stations, scrubbers, vessels, pipelines, inhibitor skids, storage tanks, and cathodic protection systems to control and automation.

Equipment Leasing & Procurement

SOKONO provide best equipment with the highest reliability sourced from reputable international companies to our clients. We supply the following equipment and devices but not limited:

- Road construction equipment

- Compressors. Pumps and Pumping Services

- Valves, Flowmeters, Pressure and temperature gauges

- Wellheads

- Pipeline connecting accessories

- Welding machine's, pipes cutting and bending machines etc

Civil Infrastructure, Design, Construction Services

- Road design, construction and inspection services

- Building construction

- Infrastructural post construction support services for oil & gas facilities

Soil and Water Engineering

- Water distribution network design and construction

- Water wells and infrastructural design and construction

- Design, construction and installation of water treatment plant

Support Services

- Logistics

- Security

- Marine support services